National Institute of Advanced Industrial Science and Technology

Dr. Yoshimitsu Okazaki

TANACBONE is a simulated bone made from Japanese CT data and developed for practicing techniques such as osteotomy, guide pin insertion, nail and lag screw insertion, cup and stem placement, screw and plate placement, reaming, anchor placement, and decompression using common orthopedic surgical instruments. The new product is simple, yet clinically relevant. It is designed to be simple, yet to enable practice in a manner similar to that of clinical practice. In addition, more advanced practice is possible by attaching muscles, ligaments, nerves, etc.

| ○ | I could see the difference between cortical and cancellous bone during screw insertion. The hands-on experience with the use of x-rays was meaningful and close to clinical practice. |

| ○ | The feel of cancellous and cortical bone was realistic. Peripheral tissues such as ligaments and muscles were also close to clinical. |

| ○ | The acetabular model also has two layers in the acetabulum, so it was good practice to see the difference in feel when entering the trabecular bone from the cortical bone during reaming. |

TANACBONE has been used in in-house evaluations during medical device development as well as in non-clinical studies for medical device applications.

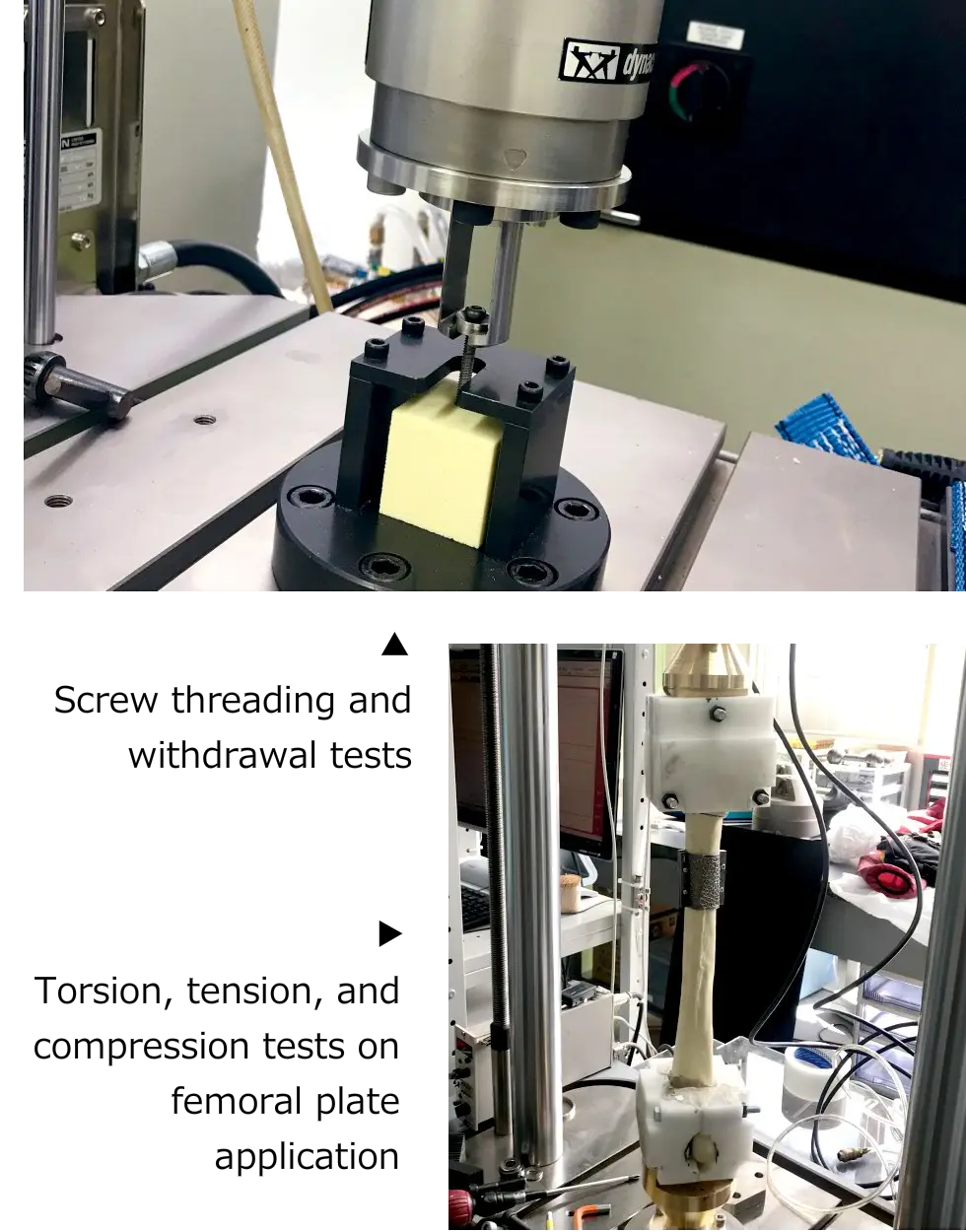

[ Example ]・Pulling test of screws using test blocks

・Plate risk validation study using a femur model

| ○ | Since the test conditions could be controlled by changing the density of the simulated bone, it was possible to conduct worst-case tests that would not be possible in a clinical trial, leading to enhanced risk management. |

※Please contact us to discuss the contents of your examination.

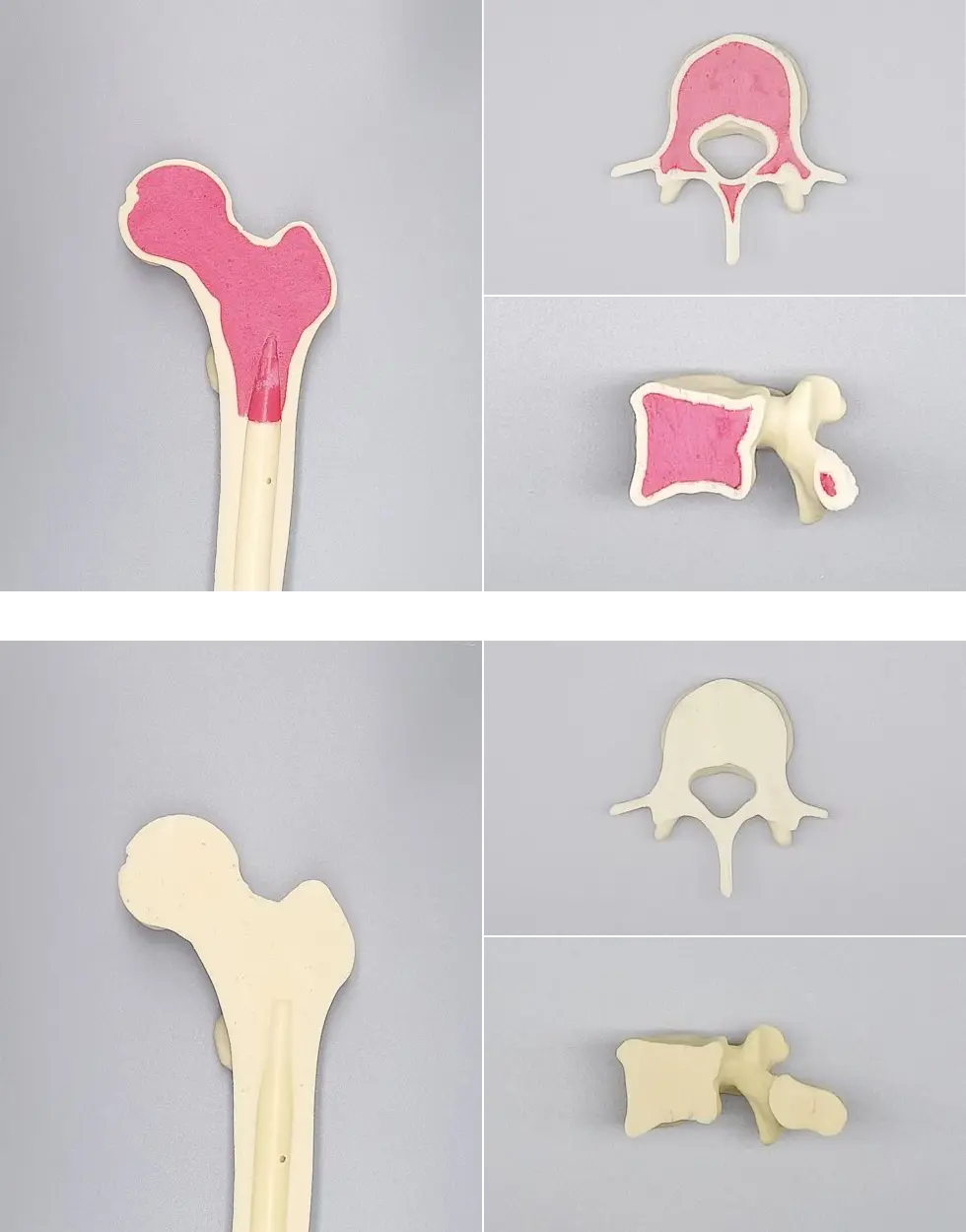

It is made of two layers of rigid polyurethane foam material with different densities.

LD (Low Density)

The softness of the cancellous bone allows for more clinical practice of techniques such as cutting, screw insertion, rasping, and reaming.

HD (High Density)

This model is made of hard cancellous bone. It is used for checking the strength of implants as well as for technique practice.

The entire piece is made of rigid polyurethane foam material or rigid urethane material of the same density.

In addition to practicing the technique, it is used to check the strength of implants.

Density can be changed for both 2-layer and 1-layer models.

Please specify the desired grade by referring to the values in the "Test Blocks" list. However, the values in the table are typical values for blocks, and may differ slightly from the values when molded into simulated bone.

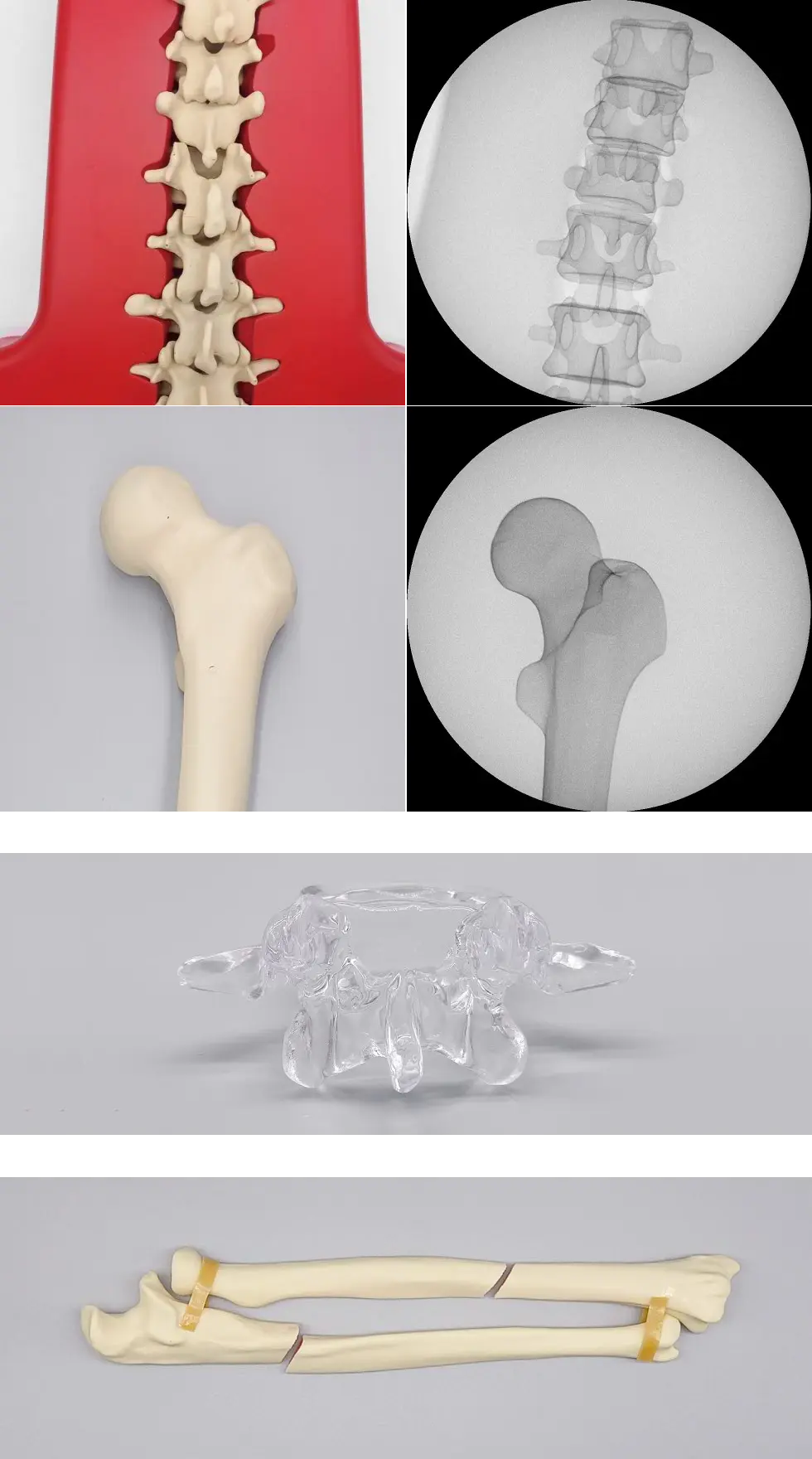

Almost all products can be processed for x-ray compatibility.

Even after processing, the density and cutting feel remain virtually unchanged.

The implants are used for display at exhibitions and other events. Molding process with inserts of supplied implants is available.

Fracture line processing and hole punchingWe can also insert fracture lines in your desired design. We can also provide detailed processing, such as a bottom hole.

※Density and dimensions of model bones are approximate. Density and dimensions may vary due to molding process.

※Due to the characteristics of the material, it may turn yellow over time, but this does not pose a problem in terms of quality or physical properties.

※For the 2-layer model, some of the color of the trabecular bone may show through.

Copyright © TANAC Co., Ltd.

Gifu University

Orthopaedic surgery, Professor

Dr. Haruhiko Akiyama

Yamaguchi University Graduate School

Orthopaedic surgery, Assistant Professor

Dr. Norihiro Nishida